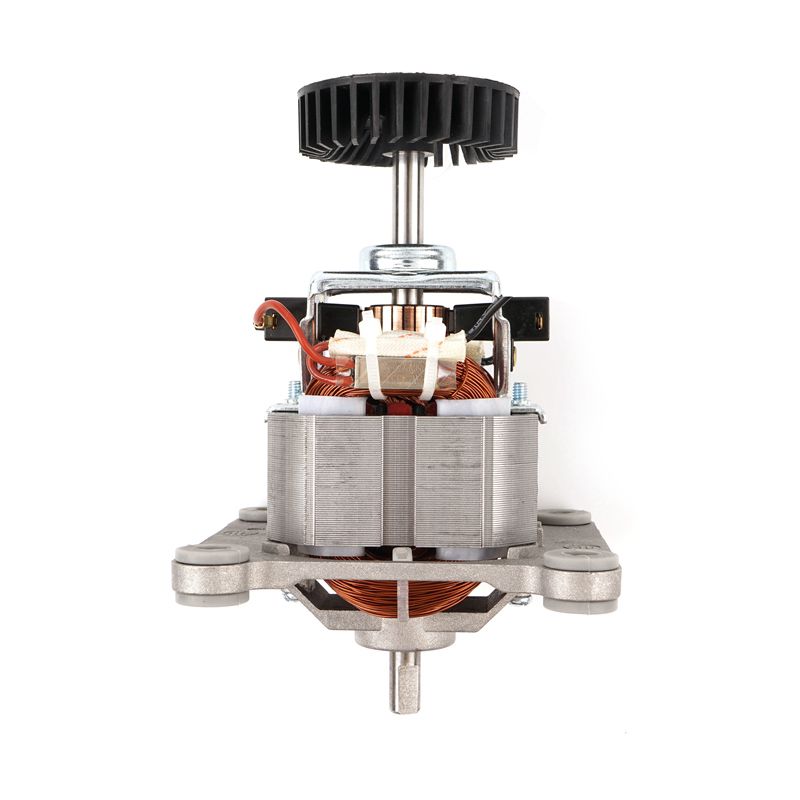

The mixer motor is usually composed of electric motor, reducer, coupling and other components. It provides power to drive the mixing shaft and agitator to rotate, so that the materials in the container can flow and shear, so as to achieve the purpose of uniform mixing.

| Origin | China |

| Voltage | 220V~230V,50 Hz |

| Logo | Custom logos are accepted |

| OEM / ODM | Availalbe |

| Packaging | Custom packaging is accepted |

| Transportation | BY SEA /BY AIR/LAND CARRIAGE |

| payment Method | T/T, L/C, D/P, PAYPAL, WESTERN UNION, CREIDT CARDS |

| Terms of Trade | EXW, FOB, CNF, CIF, DOOR TO DOOR |

| Supply Capacity | 5000000 pcs annual output |

Diverse power: The mixer motor has different power levels, which can be selected according to the nature of the mixing material, the size of the mixing container and the mixing requirements.

Wide speed regulation range: Modern mixer motors are usually equipped with speed regulating devices, which can adjust the speed as needed to meet different mixing speed and mixing effect requirements.

Compact structure: The mixer motor has a compact design, small footprint, and is easy to install and maintain.

Strong durability: Made of high-quality materials and advanced technology, the mixer motor has a long service life and high durability.

Food industry: used to make drinks such as smoothies, juices, soy milk, and mixing flour, sugar, oil and other ingredients to make food.

Chemical industry: used to mix various chemical raw materials and prepare chemical products.

Pharmaceutical industry: used to prepare biological products such as drugs and vaccines.

Laboratory: used for experimental research and sample preparation in the fields of biology, physics and chemistry.

Cleaning work: Regularly clean the inner and outer surfaces of the mixer motor to remove dirt and residues and keep the motor clean and tidy.

Lubrication maintenance: Add or replace lubricants according to the prescribed cycle to ensure the normal operation of each component and reduce wear.

Check fasteners: Regularly check whether fasteners such as bolts and nuts are loose, and tighten them in time to prevent parts from falling off or being damaged.

Observe the operating status: Pay attention to whether the sound and vibration of the mixer motor are normal. If there is any abnormality, stop the machine for inspection in time.

Check the seal: Ensure good sealing to prevent leakage and moisture from entering the motor and causing short circuit or damage.

Regularly check the electrical system: including electrical components such as wires and plugs to ensure safety and reliability and avoid safety accidents caused by electrical failures.