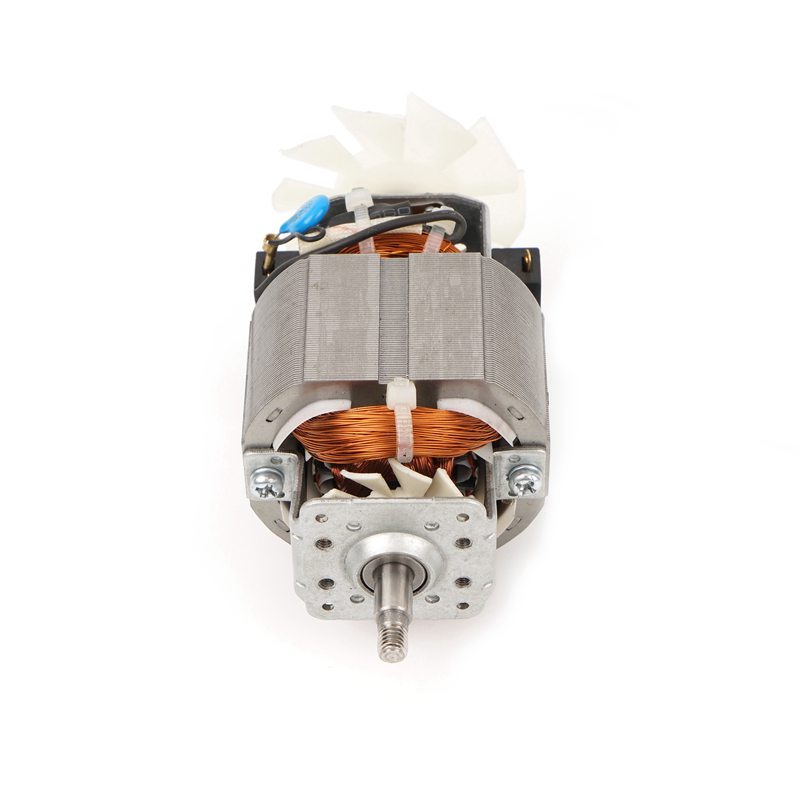

commercial blender motors are core components of blenders designed for commercial use. They provide powerful power to ensure that blenders can operate efficiently and stably. These motors usually have higher power and longer service life to meet the high requirements for blending efficiency and durability in commercial environments.

| Origin | China |

| Voltage | 220V~230V,50 Hz |

| Logo | Custom logos are accepted |

| OEM / ODM | Availalbe |

| Packaging | Custom packaging is accepted |

| Transportation | BY SEA /BY AIR/LAND CARRIAGE |

| payment Method | T/T, L/C, D/P/ PAYPAL,WESTERN,UNION, CREIDT CARDS |

| Terms of Trade | EXW, FOB, CNF, CIF, DOOR TO DOOR |

| Supply Capacity | 5000000 pcs annual output |

High power: commercial blender motors usually have higher power, which can quickly and effectively blend various ingredients and improve work efficiency.

Strong durability: Made of high-quality materials and advanced technology, the motor can maintain stable performance under long-term continuous operation.

Speed regulation function: Some commercial blender motors are equipped with speed regulation devices, which can adjust the speed according to different ingredients and blending requirements to achieve more precise control.

Compact structure: The design is compact and occupies a small area, which is easy to install and maintain.

High safety: It has protection functions such as overheating and overcurrent to ensure that the motor can be safely shut down in abnormal situations to avoid damage.

Catering industry: Used to make drinks such as juice, smoothies, milkshakes, and blend various ingredients to make special dishes.

Food processing: Used to mix and stir various raw materials to prepare semi-finished or finished foods.

Laboratory: used for sample preparation and experimental research in biology, chemistry and other fields.

Regular inspection: Regularly check the operating status of the motor, including sound, vibration, temperature, etc. If there is any abnormality, stop the machine for inspection in time.

Cleaning and maintenance: Regularly clean the dust and dirt on the surface and inside of the motor to keep the motor clean and tidy.

Lubrication and maintenance: Add or replace lubricants according to the prescribed cycle to ensure the normal operation of all parts of the motor.

Check fasteners: Regularly check whether fasteners such as bolts and nuts are loose, and tighten them in time to prevent parts from falling off or being damaged.

Avoid overload: Avoid long-term continuous operation or overload to avoid overheating or damage to the motor.

Professional maintenance: In the event of motor failure or damage, professionals should be asked to repair or replace it to ensure that the motor can be restored to normal use.

With the continuous development of commercial kitchens and food processing industries, the demand for blender motors is also increasing. In the future, commercial blender motors will develop in the direction of higher power, finer control, and more intelligence to meet the changing market needs. At the same time, concepts such as environmental protection and energy saving will gradually be integrated into the design and manufacturing of commercial mixer motors, promoting the sustainable development of the entire industry.