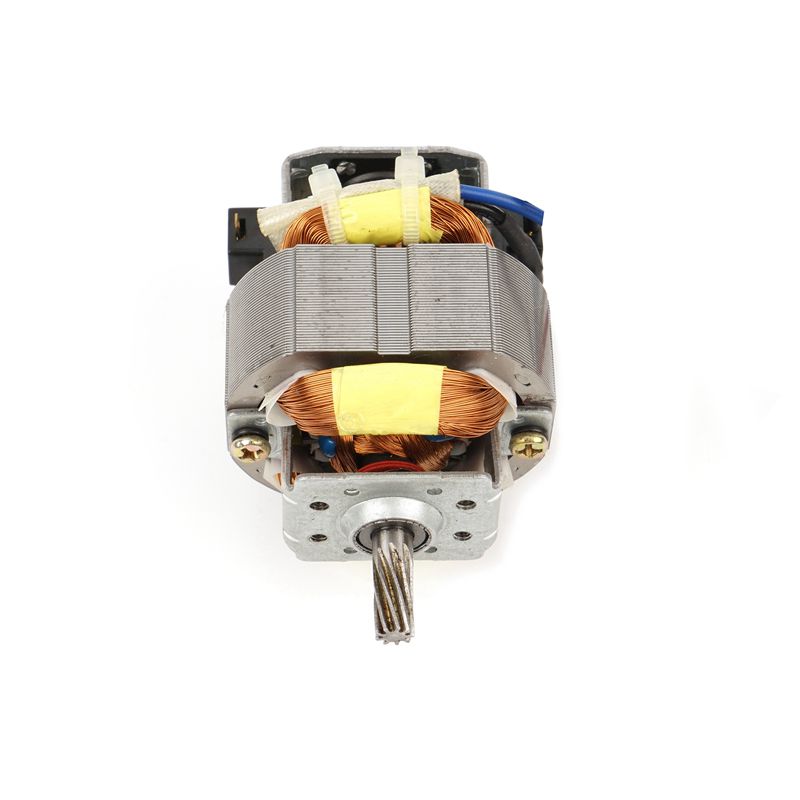

DC 220v Blender Motor, that is, DC 220 volt blender motor, is a DC motor designed for blenders.

Origin: China

Voltage :220V~230V,50 Hz

Logo: Custom logos are accepted

OEM / ODM: Availalbe

Packaging: Custom packaging is accepted

Transportation:BY SEA /BY AIR/LAND CARRIAGE

payment Method:T/T, L/C, D/P, PAYPAL, WESTERN UNION, CREIDT CARDS

Terms of Trade:EXW, FOB, CNF, CIF, DOOR TO DOOR

Supply Capacity: 5000000 pcs annual output

DC power supply: It is powered by a DC 220 volt power supply with stable current output, which is suitable for equipment such as blenders that require stable power output.

Simple structure: The structural design of the DC motor is relatively simple, without a complex electronic controller, which makes its manufacturing cost low and easy to install and maintain.

Large starting torque: The DC motor can provide a large torque at startup, which is very beneficial for applications that require fast response and heavy load startup.

Easy speed control: By changing the input voltage or current, the speed of the DC motor can be easily controlled to meet the needs of the blender under different working conditions.

Stable operation: Under constant load, the DC motor can provide stable operating performance to ensure the stable operation of the blender.

DC 220v Blender Motor is mainly used in various types of blenders, such as kitchen blenders, industrial blenders, laboratory blenders, etc. These devices usually require stable power output and precise speed control to meet different mixing needs. In addition, DC motors are also widely used in small equipment, toys, door and window automation and other fields due to their simple structure and low maintenance costs.

Regular inspection: Regularly check the appearance, connecting wires and connectors of the motor to ensure that there are no cracks, deformation, wear or aging.

Clean the motor: Regularly clean the surface and inside of the motor to avoid dust and dirt accumulation that affects heat dissipation and operating efficiency. Use a clean soft cloth or air blower for cleaning, and avoid using corrosive cleaning agents.

Check the temperature: Use a temperature sensor to monitor the operating temperature of the motor to ensure that it is within the safe range. If the temperature is found to be abnormally high, stop the motor immediately for inspection and find out the cause.

Lubrication and maintenance: Although DC motors are usually not designed to require frequent lubrication, in some cases, proper lubrication can reduce friction and extend the life of the motor. Lubricate according to the manufacturer's recommendations to avoid excessive lubrication that causes oil accumulation.

Load test: Perform load tests regularly to check the motor's speed, torque, efficiency and other parameters to ensure that it works normally within the design range.

Avoid overload operation: Reasonably configure the load according to the rated parameters of the motor to avoid overheating or damage to the motor due to overload.