Alternating Current AC Motor is a motor device driven by AC power, which can efficiently convert electrical energy into mechanical energy. The rotating magnetic field is generated by the stator coil, which drives the rotor to rotate and achieves continuous and smooth power output.

| Origin | China |

| Voltage | Dc12-36v |

| Logo | Custom Logos Are Accepted |

| Oem / Odm | Availalbe |

| Packaging | Custom Packaging Is Accepted |

| Transportation | By Sea /by Air/land Carriage |

| Payment Method | T/t, L/c, D/p, Paypal, Western Union, Creidt Cards |

| Terms Of Trade | Exw, Fob, Cnf, Cif, Door To Door |

| Supply Capacity | 5000000 Pcs Annual Output |

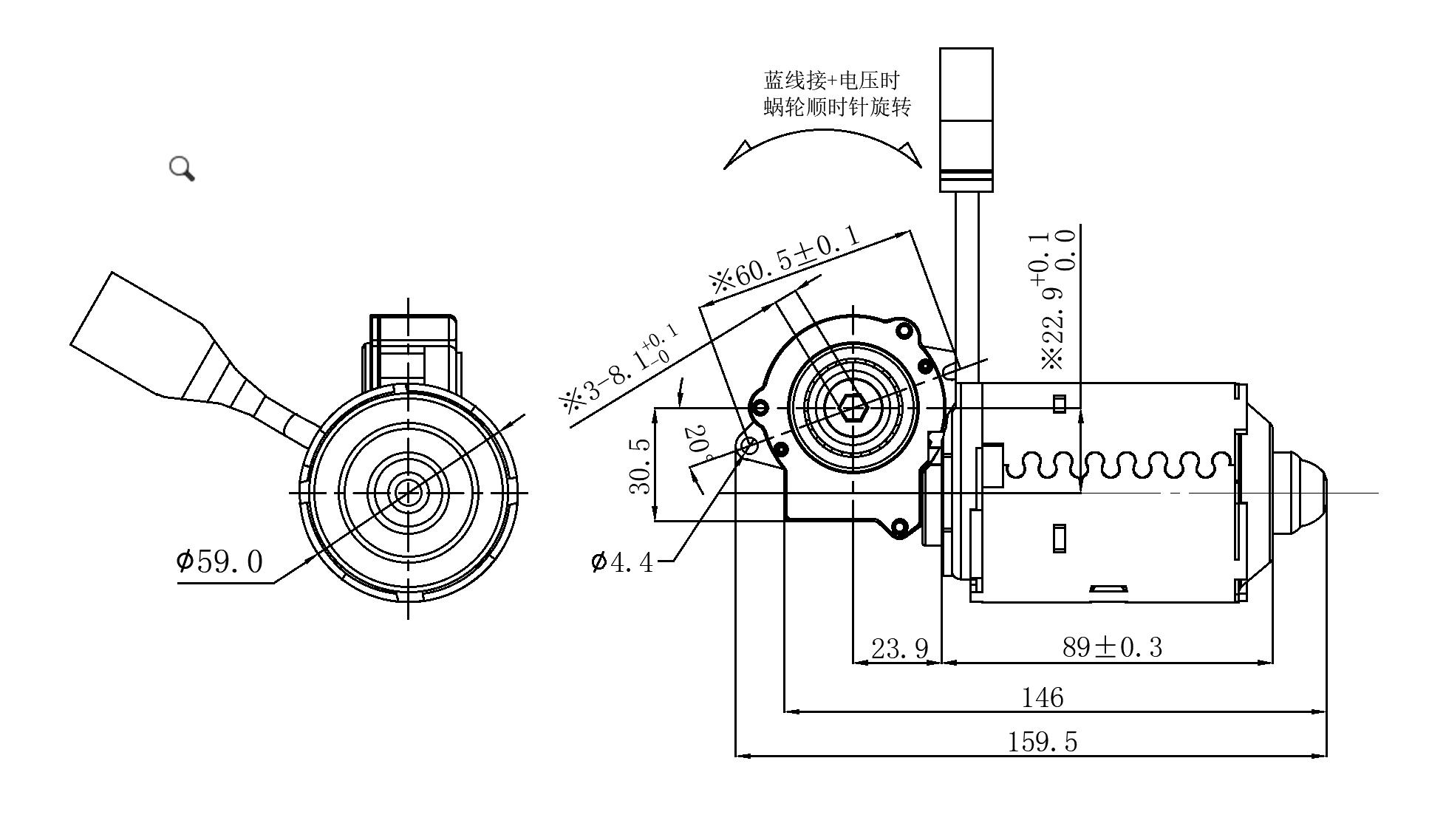

| Rataed Speed | 70-100rpm |

| Rated Output Power | Low Voltage Does Not Specify Power And Grade |

| Motor Diameter | 150-180mm |

| Typical Application | Lift Table |

High load continuous operation capability

The motor is designed to adapt to long-term high-load working environment. Even when the rated current is close to full load, the temperature rise remains stable and it is not easy to overheat.

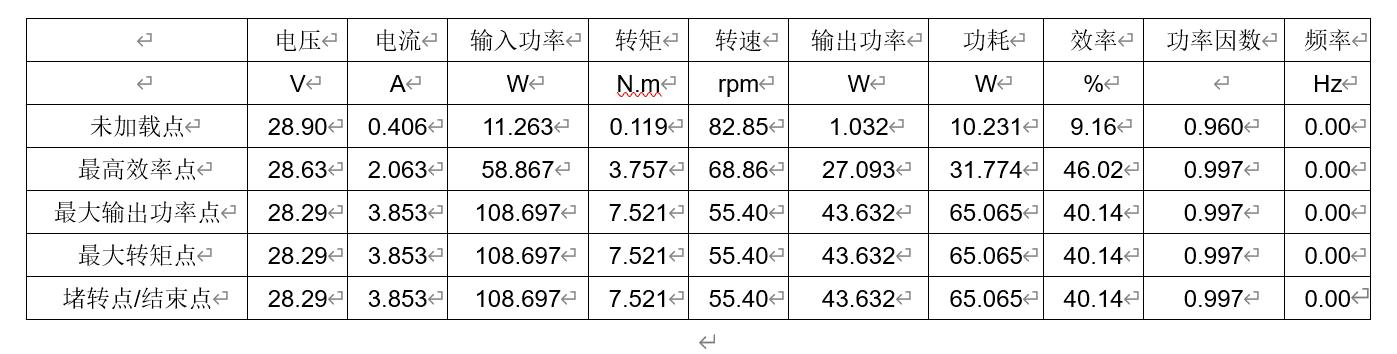

Fast dynamic response and strong starting torque

The motor has a fast initial acceleration response and a high starting torque. It can start stably and quickly reach the working speed even under the starting load state.

Low operating noise and weak vibration

By optimizing the internal magnetic field configuration and the rotor balance structure, the operating noise is greatly reduced to ensure quiet and smooth operation of the equipment.

Compact structure and flexible installation

The overall volume is compact and occupies little space. It is suitable for various cabinets, housings or embedded systems, which is convenient for modular integration of multiple devices.

Precise matching of electrical performance

The voltage, current and frequency response have been carefully tested, with strong stability, and can adapt to the precise control requirements under different power supply conditions.

Automatic control systems are used in the industrial automation industry to help achieve high-precision process control and stable equipment drive

In automated assembly lines or robotic systems, AC motors ensure a continuous power source for equipment and achieve a high-efficiency work rhythm.

Air power units are used in the HVAC industry to help drive fans and compression systems efficiently

Through stable output and continuous operation characteristics, the efficient and coordinated operation of various components of the HVAC system is guaranteed.

Conveying equipment is used in the logistics and transmission industry to help ensure the stable and uninterrupted operation of the conveyor belt system

It is used to drive modules such as rollers and electric rollers to improve logistics efficiency and equipment life.

Medical auxiliary devices are used in the precision medical equipment industry to help achieve low noise and constant speed operation

Especially suitable for laboratory instruments, pump systems and surgical support equipment, which have extremely high requirements for stability and quietness.

Mold machinery is used in the injection molding and die-casting industries to help the efficient execution of mold opening and closing and clamping systems

Relying on large torque output and reliable response time, it improves equipment operating efficiency and reduces mechanical wear.