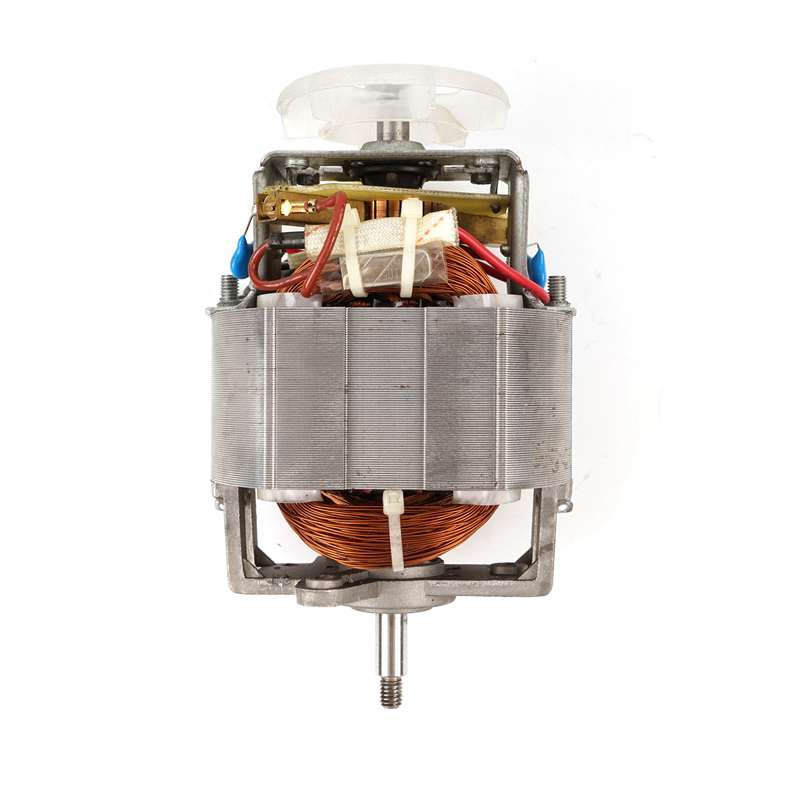

As a prominent Meat Grinder Electric Motor Factory, JUNHUI ELECTRIC MANUFACTURE CO. LTD. is dedicated to the production of high-end Electric Motors for Meat Grinders. Operating at 220V~230V and a frequency of 50Hz, this motor ensures optimum performance in grinding activities. This universal motor consists of copper windings and durable assemblies to provide constant torque and efficiency with various applications such as a home and commercial meat grinders. OEM and ODM as well as custom logos and packaging can be offered, thus practical and suitable for various household appliances manufacturers. Carrying out more than 5 million units each year, “JUNHUI” promises fast and reliable export of high quality motor solutions around the world.

The electric motor for meat grinders is designed to deliver high torque, ensuring it can efficiently process different cuts and textures of meat without bogging down or stalling.

These Meat Grinder Gear Motors are known for their reliable and consistent performance, meeting the demands of continuous operation in meat processing. They contribute to the overall efficiency of the meat grinder.

The AC Universal Motor for Meat Grinders are constructed with durability in mind, featuring robust components that can withstand the demands of the meat processing environment. This ensures a longer lifespan and minimizes downtime.

Tailored to the specific needs of meat grinding, these Meat Grinder Motors facilitate efficient processing of meat, producing consistent results in terms of texture and fineness.

Many Electric Motor For Meat Grinders are compatible with variable speed control, allowing operators to adjust the grinding speed based on the specific requirements of the meat being processed.

Some Motor Electric Meat Grinder Motors are designed for quiet operation, minimizing noise during the meat grinding process. This can be beneficial in various settings, including commercial kitchens and processing facilities.

These motors are designed for easy integration into meat grinder systems. Their standardized design allows for seamless replacement or upgrading of motors in existing equipment.

Electric Motor For Meat Grinders come in various sizes and power ratings, allowing for adaptability to different grinder models and sizes, catering to the diverse needs of the industry.

Origin: China

Voltage :220V~230V,50 Hz

Logo: Custom logos are accepted

OEM / ODM: Availalbe

Packaging: Custom packaging is accepted

Transportation:BY SEA /BY AIR/LAND CARRIAGE

payment Method:T/T, L/C, D/P, PAYPAL, WESTERN UNION, CREIDT CARDS

Terms of Trade:EXW, FOB, CNF, CIF, DOOR TO DOOR

Supply Capacity: 5000000 pcs annual output

Commercial Meat Processing Facilities:

Electric motors for meat grinders are widely used in large-scale commercial meat processing facilities where high-volume and continuous meat grinding is required.

Food Manufacturing Plants:

Large-scale food manufacturing plants incorporate electric motors for meat grinders in their processing lines to efficiently produce ground meat for a wide range of food products.

Catering Companies:

Catering companies employ meat grinders with electric motors to prepare ground meat for catering events, ensuring consistency and quality in meat-based dishes.

Electric motors for meat grinders come in various power ratings, typically ranging from smaller units suitable for home use to larger, high-powered motors for commercial and industrial applications.

Compatibility can vary, and it's advisable to check with the manufacturer or supplier to ensure that the electric motor is suitable for the specific meat grinder model.

Safety features may include overload protection, thermal protection to prevent overheating, and secure mounting options. Manufacturers often design these motors with user safety in mind.

Some models are designed to handle frozen meat, but it's essential to check the specifications to confirm the motor's capability for processing frozen or tougher cuts.

OUR MANAGEMENT

We also pay attention to the sustainable development of the enterprise and brand building, and regard actual execution as the core of enterprise management. Through strict implementation of quality management, standardized production and process optimization, we can improve enterprise management efficiency and customer satisfaction, and promote the healthy and stable development of the enterprise.

OUR FUTURE

The future goal and vision of Junhui Motor Co., Ltd. is to become an internationally leading motor manufacturing enterprise with a sense of social responsibility and good credibility. With quality, service, innovation and environmental protection as the core competitiveness, the company, customers, employees and society will achieve common development and common prosperity. We firmly believe that only by achieving a balanced development of social benefits, economic benefits and environmental benefits can an enterprise continue to develop and grow. We strive to make unremitting efforts to create a better world, so that Junhui Electric Co., Ltd. can become a brand with leading position and competitive advantage in the industry.

JUNHUI ELECTRIC MANUFACTURE CO.,LTD. is a micro motor manufacturer who dedicated to the research, development, and production of Universal motors, PMDC motors, Shaded Pole motors and related drive solutions. The products and solutions we provide are widely used in multiple areas such as home appliances, power tools, , personal care devices, commercial appliances, health care devices, and so on.

JUIHUI has been approved ISO 9001:2015 quality management system, and won the title of National High-tech Enterprise in 2021, Our universal motor, DC motor and Shaded pole motor are in line with CE and ROHS standards. And we have an experienced R&D team and quality control department to provide customers with customized and high-quality products.

JUIHUI has high level automated production lines and advanced testing equipment, annual capacity reach 5 million units. And we also produce motor hardware parts such as shaft, bracket etc, ensure products' quality and competitive prices. In addition, we also have a professional business team, to provide customers with flexible and professional services to achieve mutual benefit and win-win cooperation.

10+year experience in electric motor manufacturing

Annual Capacity: 5 million units

20+ automatic and semi-automatic production lines

300+ employees

20,000+ square meters area