A hair dryer is an essential home appliance in modern life, and one of its core components is the Hair Dryer Motor. This article will delve into the working principle of Hair Dryer Motors and the manufacturing process involved in producing these motors.

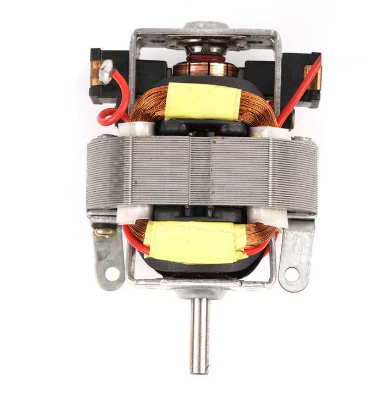

Working Principle of Hair Dryer Motors: Hair dryer motors are alternating current (AC) Electric Motors that rely on the interaction between the magnetic field generated by the current passing through the coils and the permanent magnet in the motor to produce mechanical work. When current flows through the motor's coils, a magnetic field is created. This field then interacts with the permanent magnet, causing the motor's rotor to rotate.

Manufacturing Process of Hair Dryer Motors: The manufacturing process of hair dryer motors can be divided into several steps:

Casting or machining the motor's casing: Hair dryer motors usually have casings made of metal or plastic. The desired shape and structure of the motor's casing are achieved through casting or machining techniques.

Coiling the motor's wire: The wire coils are crucial components of the hair dryer motor. They are made by winding conductive wires on the motor's iron core.

Installing the permanent magnet: Hair dryer motors typically utilize rare-earth permanent magnets. These magnets are installed on the motor's iron core to facilitate the interaction with the coils.

Assembling other key components: The motor's rotor, bearings, gears, and other essential parts are assembled together to complete the hair dryer motor.

Hair Dryer Motor factories: Hair dryer motors are primarily manufactured in specialized hair dryer motor factories. These factories possess advanced production equipment and technologies to produce high-quality hair dryer motors according to market demands. Additionally, they prioritize quality control and production efficiency to ensure product quality and timely delivery.

Conclusion: Hair dryer motors are critical components of hair dryers, and their working principles and manufacturing processes have a significant impact on the performance and quality of the hair dryer. Manufacturing high-quality hair dryers requires advanced manufacturing techniques, equipment, and superior hair dryer motors. By enhancing the production capacity and quality control measures in hair dryer motor factories, it is possible to produce higher-quality hair dryer products that meet consumers' demands for efficiency and safety.