Whisking is a fundamental technique in cooking and baking, and having a reliable and efficient whisk motor is crucial for achieving perfectly mixed, fluffy, and delicious results. This article explores the significance of whisk motors, the importance of selecting the right whisk motor supplier, the manufacturing process, and the role of DC Motors in powering these essential kitchen appliances.

The Significance of Whisk Motors: Whisk motors play a pivotal role in transforming manual whisking into a convenient and effortless process. These compact motors, usually powered by DC motors, provide the necessary torque and speed to swiftly rotate the whisk blades. By automating the whisking process, these motors ensure consistent mixing, save valuable time, and reduce physical strain.

Selecting the Right Whisk Motor Supplier: When it comes to whisk motors, choosing a reputable and reliable supplier is paramount. A trustworthy whisk motor supplier offers several benefits, including:

Quality assurance: A reliable supplier ensures that their motors are manufactured using high-quality materials and cutting-edge technology, resulting in durable and efficient whisk motors.

Customer support: A reputable supplier provides excellent customer service, offering technical assistance, troubleshooting guidance, and quick response times to address any concerns.

Variety and customization: A trusted supplier offers a diverse range of whisk motors to cater to different needs and specifications. They may also provide custom motor solutions tailored to specific applications.

The Manufacturing Process of Whisk Motors: The manufacturing of whisk motors involves a series of meticulous steps, including:

Design and engineering: Expert motor engineers develop a Motor Design that meets the requirements of efficient whisking, ensuring the proper balance between power, speed, and noise levels.

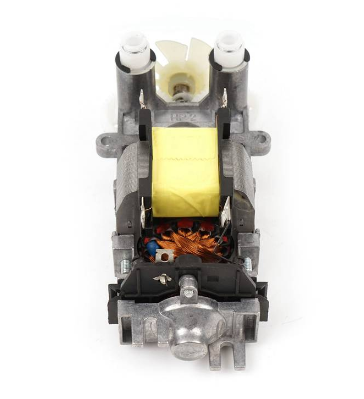

Component selection: A reliable manufacturer selects high-quality components, such as copper wire for the motor coils and durable housing materials, to ensure optimum performance and longevity.

Assembly and quality control: Skilled technicians assemble the motor, integrating all the components and conducting rigorous quality control tests to verify functionality, efficiency, and safety standards.

The Role of DC Motors in Whisk Motors: The majority of whisk motors employ direct current (DC) motors due to their numerous advantages, including:

Efficiency: DC motors offer high efficiency levels and precise control over motor speed and torque, ensuring optimal performance during whisking.

Compact size: DC motors are relatively small, making them ideal for compact kitchen appliances like whisk motors.

Quiet operation: DC motors operate smoothly and quietly, allowing users to whisk without disturbing the ambience of their kitchen.

Conclusion: Whisk motors powered by DC motors are essential kitchen appliances that simplify and enhance the whisking process. Choosing a reliable whisk motor supplier ensures access to high-quality motors, exceptional customer support, and customized solutions. Through meticulous manufacturing processes, these suppliers create whisk motors that deliver consistent performance, efficiency, and longevity, resulting in delightful culinary experiences with every whisk.